In electronics, Printed Circuit Boards (PCBs) and semiconductor chips form a dynamic duo, working in perfect harmony. Each plays a distinctive role while tightly collaborating to drive the functionality of electronic devices. PCBYES specializes in small- and medium-scale PCBA one-stop services.

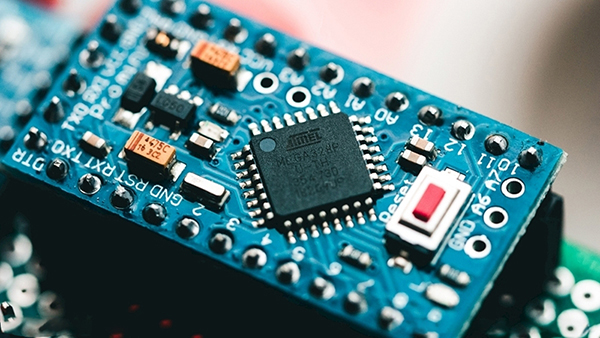

From a structural perspective, PCBs are the foundational platform for electronic components, while chips are highly integrated modules performing complex electronic functions. A PCB, constructed on an insulating substrate, features intricately arranged copper traces that form a sophisticated network of circuits. These traces, designed by schematics, mechanically support and electrically interconnect various electronic components. In contrast, a chip—often referred to as the "brain" of modern electronics—houses billions of microscopic transistors, enabling powerful data processing, storage, and signal conversion capabilities.

Take a smartphone as an example. The central processing unit (CPU) chip executes applications and manages system tasks, while the storage chip handles data read/write operations. These chips are mounted on the PCB, which connects them to other components like cameras, displays, and communication modules through its meticulously designed circuitry.

Signal Transmission: The Core of Collaboration

The collaboration between PCBs and chips is particularly evident in signal transmission. Chips generate or receive electrical signals via their microscopic pins. These pins align with corresponding pads on the PCB—akin to "signal docks"—enabling precise electrical connections. The signals are then routed along pre-designed copper traces to their destinations.

For instance, when a smartphone's CPU processes a user’s screen touch input, it sends display signals to the display driver chip. This signal journey begins at the chip, traverses the PCB’s conductive pathways, and reaches the target chip with precision. Any disruption, such as a break, short circuit, or poor connection in these pathways, can impede signal flow, causing screen glitches or system crashes.

Heat Dissipation: Ensuring Stability and Performance

Efficient heat dissipation is another critical aspect of PCB-chip synergy. During high-speed operations, chips generate significant heat, which, if not managed, can degrade performance or even lead to chip failure. PCBs are designed with heat dissipation in mind, aligning with the thermal characteristics of the chips they support.

This is achieved in two primary ways:

- Copper Traces: Large copper areas on PCBs utilize copper's excellent thermal conductivity to dissipate heat away from chips.

- External Cooling Solutions: Heat sinks, fans, or other cooling components are often integrated to create an optimal operating environment for chips.

For example, the PCB beneath a computer motherboard’s CPU often includes multiple layers of copper, complemented by a high-efficiency cooling fan, ensuring the CPU operates reliably under heavy workloads.

Driving Innovation Together: Advancing with Technology

As electronic products evolve, the interplay between PCBs and chips also advances. Chips are becoming smaller and more powerful, setting higher requirements for PCB design and manufacturing.

Modern PCBs must meet the demands of high-frequency, high-speed signal transmission for advanced chips. This involves using low-loss dielectric materials, optimizing microstrip and stripline designs, and maintaining precise impedance control to minimize signal degradation and reflection.

Additionally, packaging technologies are advancing from traditional methods to System-in-Package (SiP) designs, where PCBs and chips integrate even more closely. In SiP configurations, multiple chips and passive components are packaged together in compact PCB modules, reducing device size and enhancing integration.

PCBs and chips are indispensable elements of the electronics industry. Their collaboration underpins the progression of electronic products, enabling them to transition from simple to complex, from inefficient to highly efficient systems.

At PCBYES, we specialize in small- and medium-scale PCBA one-stop services. With a professional team and advanced equipment, we deliver high-quality PCBs tailored for a wide range of chips, supporting the growth of the electronics industry. Stay tuned for more insights into cutting-edge electronic manufacturing trends.